Mimaki Launches Environmentally Conscious, Two-Step Textile Transfer Printing Solution TRAPIS

Mimaki Europe has announced the commercial release of its textile pigment transfer printing system, named “TRAPIS”. Following the preview of the technology at ITMA 2023, this commercialised version, available later this year, offers an environmentally friendly and easy to operate solution for textile applications – saving almost 90% of wastewater compared to conventional methods.

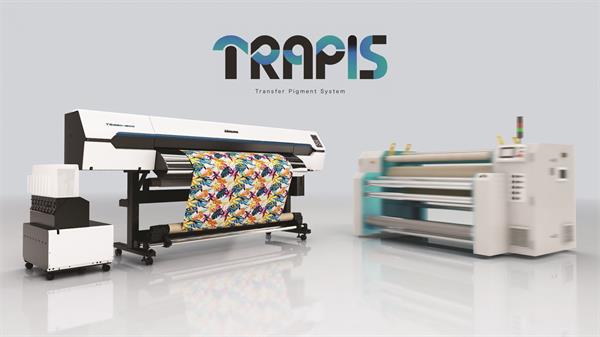

Simple two-step processTRAPIS provides a simple two-step process, consisting of an inkjet printer and a calender. The design of choice is printed by the inkjet printer with a dedicated ink onto transfer paper, which is then transferred to the application via a calender. Unlike both analogue and digital conventional dye-printing methods, TRAPIS generates almost no wastewater, only that which is produced during the printer’s automatic maintenance. Due to no pre-treatment or washing of the fabric being needed, this saves around 14.5 litres per square metre of water when compared to digital dye printing.*1

Additionally, this eliminates the need for wastewater treatment facilities, which can be both expensive and constrictive when it comes to where the solution is installed. Due to the smaller size, it is possible for the TRAPIS system to be installed in a limited space, or even at the front of a print shop.

TRAPIS also offers print service providers an easy to use option for textile printing. As the process only involves printing and transferring, it does not require specialised skills to operate when compared to the more complex seven or eight step system for digital and analogue conventional printing. The lack of a fabric conveyor belt in the system further minimises the need for time intensive maintenance.

Print to a range of materialsFurther simplifying the process, TRAPIS is able to print on a wide range of materials, including natural fibres like cotton and silk in addition to blended fabrics, with just one type of ink. Due to this, the process can be flexible and adapt to customer demand, even with multi-material short runs. The accompanying ink has also achieved the ZDHC MRSL Lv.3*2 certification and is bluesign APPROVED, to ensure that it is both worker and consumer safe, as well as an environmentally friendly product. As with Mimaki’s existing textile solution portfolio, the prints produced with TRAPIS maintain stretchability and colourfastness, without impacting aspects like breathability and water absorbability, important for sectors like home textiles, activewear and fashion.

|

Arjen Evertse, General Manager Sales, Mimaki Europe, comments, “After the positive reception we received when we initially showcased the technology last year, we’re pleased to now announce the release of this solution commercially at FESPA. Conscious of the evolving sustainability standards and customer demands, we created TRAPIS as an innovative and seamless system for print service providers looking to produce high quality and vibrant textile applications, while keeping cost, time and environmental impact to a minimum.”

For further information on the TRAPIS system and the full Mimaki product line-up, visit

www.hybridservices.co.uk*1: According to Mimaki’s original research, digital dye printing generates significant amount of wastewater by textile printing conveyor belt washing and fabric washing after dye fixation (steam)

*2: ZDHC is a non-profit organisation based in Amsterdam, the Netherlands, that works to eliminate the emission of hazardous substances in the textile and leather industry.